(Originally appeared on this twitter thread)

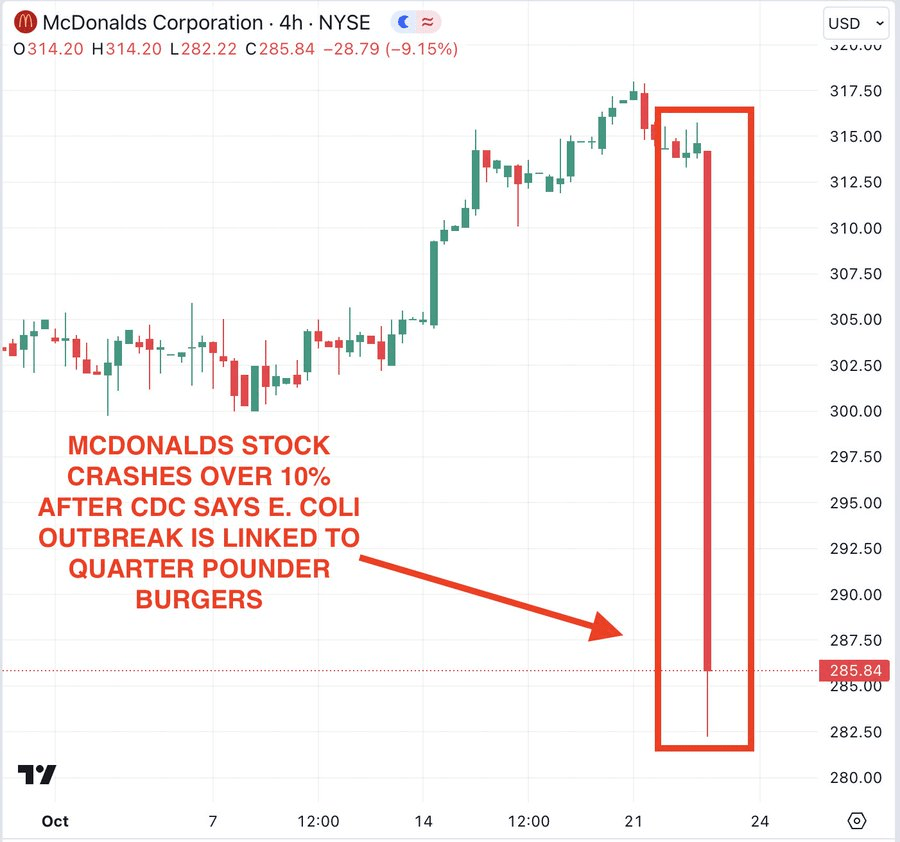

As population consumption needs rise, food production and processing is trying to keep up. Food recalls increased by about 40% in 2024.

But why are E. coli outbreaks at McDonald’s and Chipotle common? There’s lots of answers including the complexity of supply chains, but for consumer facing fast food, the answer often boils down to one suspect. Uncooked veggies. Veggies are washed but seldom tested before they’re packed for use at restaurants or grocery chains like Target, Walmart, or even Disney parks. On a burger line at a restaurant or a food stand, the patties are cooked, but the lettuce and onions and tomatoes?

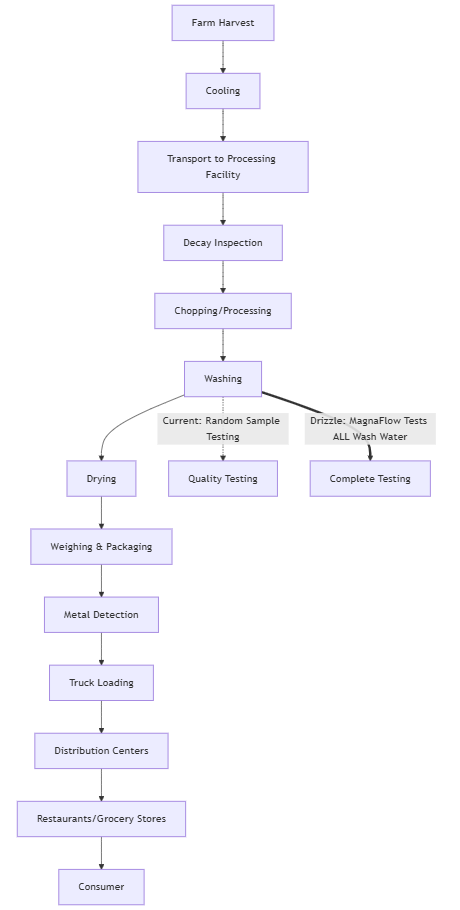

The Lettuce Supply Chain Problem

Lettuce dominates US salad consumption – 3.7+ billion pounds produced annually, mostly from California and Arizona. Here’s how it moves:

Critical Time Constraints: Total shelf life is only 12 days. Processing facilities (Taylor Farms, Fresh Express) must minimize handling time (3-15 hours) to ensure enough shelf life remains after shipping to Kroger, Costco, or Giant Food.

Temperature Is Everything: Temperature serves as the primary bacterial contamination surrogate. Facilities maintain lettuce as close to 32°F as possible. Each degree above 41°F costs a day of shelf life—tracked even in shipping trucks.

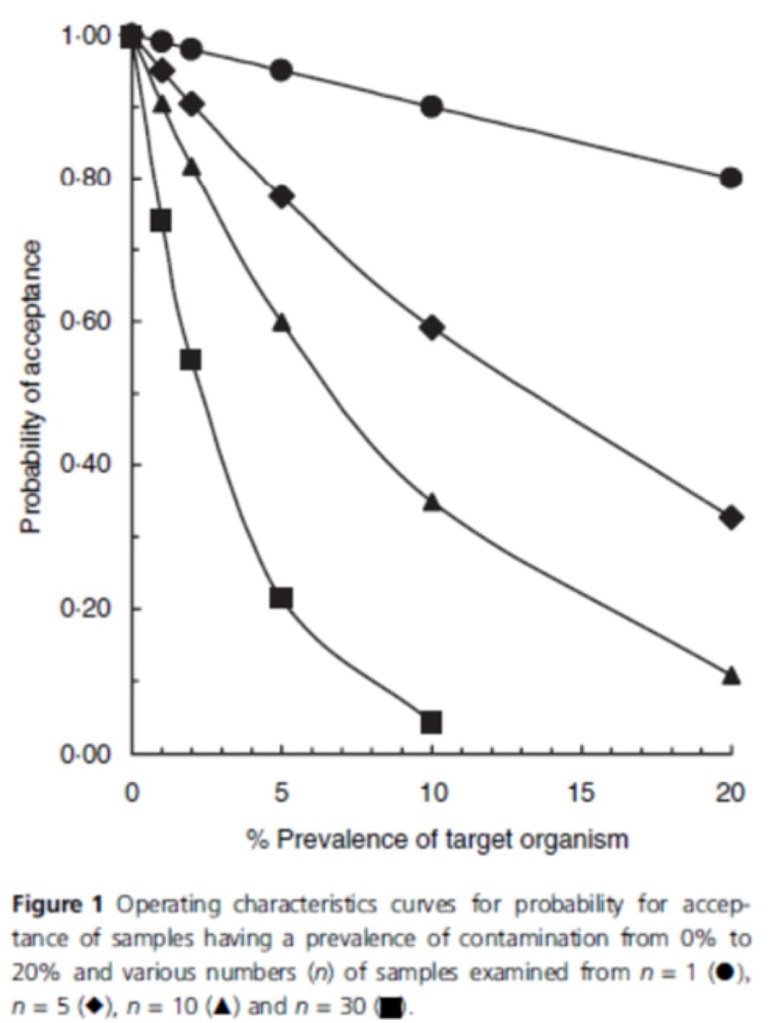

The Fundamental Testing Failure

This graph reveals the core problem. Due to minimized processing time, it’s impossible to properly test lettuce through traditional sampling:

- You can’t swab entire lots—random sampling is the only option

- Bacterial distribution is heterogeneous and often at low concentration while at facilities

- For lower prevalence contamination, you need exponentially more samples

Look at the graph: When contamination prevalence is low (left side), the probability of detection plummets unless you drastically increase sample numbers. Even at n=30 samples, you’ll miss most contamination below 5% prevalence.

Regulatory Gap: Unlike meats, USDA doesn’t mandate food inspection and government safety officers on-site for produce processing. This gap costs approximately $4.5 billion yearly in foodborne illness healthcare expenses.

The Cybersecurity Parallel

The entire problem mirrors cybersecurity—very large amounts of data (lettuce) need to be tested before entering the network (our food chains). While not frequent for each brand, outbreaks cost $10K-$100M per instance depending on the brand’s size.

What Drizzle Health is doing

A few key things:

- MagnaFlow System: Uses ALL wash-water through testing—not just random samples. No E. coli-carrying lettuce leaf escapes detection. We’re automating the entire sampling problem.

- Seamless Integration: Working with manufacturers’ existing processing and diagnostic infrastructure—PCR, culture, microscope—lowering both integration and testing costs while delivering safer products to Wendy’s, McDonald’s, etc. So that production is not disturbed or slowed down.

- Medupi System: Our AI-enabled 10 second bacterial recognition system that works with MagnaFlow. So lettuce lots can be attested before they leave the factory. Today, because it takes so long to both enrich and test (PCR or culture), the tests basically aren’t complete before the product has to leave the facility.

Beyond Food Safety

Food safety has improved since the 2006 outbreak, mostly through better SOPs. But despite cool tech for E. coli diagnostics, the sampling problems of scale and enrichment time have remained unsolved for biosecurity.

As population and consumption needs increase, food safety testing must evolve. The current sampling-based model not only endangers food systems but limits a future where automated background environmental surveillance for pathogens can exist. As an industry, IVD and diagnostics are in this moment too focused on high fidelity information (PCR for example). This food supply chain problem arises from the diagnostic system in food safety being modeled and built around the weakness of PCR – this time it takes, and the amount of sample it can handle. To solve this, we must shift focus to an older mindset in global health : What is the minimum amount of information required to make a decision? What we find is a lower need for high fidelity information, which can then enable faster and larger testing rates (i.e. highly efficient bacteriological/virologic screening).

Our large sampling approach is already increasing TB test sensitivity from 50% to 95% at 1/10th of PCR costs in India. Learn more about our Large-Scale Diagnostics (LSD) approach: https://digvijay.blog/2024/08/05/large-scale-diagnostics/

Leave a comment